Swiss laser cutting services outperform most mechanical cutting operations for applications that demand precision and exacting definition. Our CNC machine is purpose-built for precision laser cutting, able to produce an extremely small, high-focus Swiss laser beam. While laser Swiss cutting is not a go-to solution for every application, it is beneficial for delicate, high-precision work requiring complicated and clean cuts. With Marver Med’s fully automated CNC laser cutting services, we can quickly create tiny features and corners, producing parts in various volumes from a single set-up.

Laser cutting is a computerized process that uses a high-powered laser beam to cut materials. The strength of the laser melts, burns, or vaporizes the material to produce a precision cut and clean edge. It is a versatile, precision cutting process that can cut simple or complex shapes and be used for engraving. The new industry standard for cutting 2D parts from sheet materials, CNC laser cutting offers precision advantages for applicable benefits in producing intricate components, tight tolerances, and more.

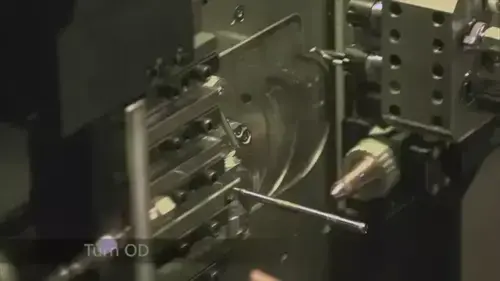

Compared to other cutting processes, CNC laser Swiss cutting offers a wide range of benefits. Laser cutting does not apply physical pressure during the cutting process, so laser-cut metal is precisely defined and clean. Our specialized process and state-of-the-art equipment are easily applicable when cutting thin or fragile materials to ensure they are not damaged or warped. Other benefits of precision laser cutting include:

Our unique Swiss cutting technology eliminates chatter-inducing vibration associated with traditional cutting tools while allowing a faster cutting process. Highly accurate laser cutting allows for lower lead times and can handle complex tasks while producing less waste and consuming less power than other cutting methods.

Using a fully computerized system, our laser-cutting services produce consistent, complex, and sophisticated elements for various industrial applications. Precision cutting with laser Swiss machining can be applied to the following materials:

If you are unsure if your material is suited to laser Swiss machining, contact Marver Med and our experts can help you find the best solution for your application.

The benefits of laser cutting translate to many industrial manufacturing processes. Offering versatility and precision, CNC Swiss cutting can be used in the following applications but is not limited to:

Many industries demand tight tolerances and exact machining for components to operate as intended. Working with unique and exotic materials, we offer precision laser cutting to produce complex and intricate components for industrial applications. Laser Swiss cutting services may not be suited for all applications but can be particularly appropriate for specific industries, such as:

Offering decades of experience working with precision cutting machinery, we can produce custom-machined hardware to match the needs of your applications, even for industries not included above.

Marver Med is an ISO 13485:2016 certified company with quality standards that meet or exceed both ANSI/ASQ z 1.4 and capabilities for Military Standards and Specifications. We offer a selection of micro-turning and precision machining services, working with a variety of unique materials for special applications in demanding industries. Operating under the umbrella of Primo Medical Group, core competencies include:

We are devoted to consistently meeting and surpassing our customer’s quality requirements and expectations while continuously striving to improve ourselves. To learn more about our dedication to maintaining the highest quality of product and service, visit our Quality Assurance page.

With over 75 years of high-precision CNC machining experience, Marver Med has the technical expertise to produce high-quality CNC machined devices, implants, and parts. For further questions about our commitment to quality or how our CNC laser cutting services can benefit your industrial applications, contact us or request a quote to get started.